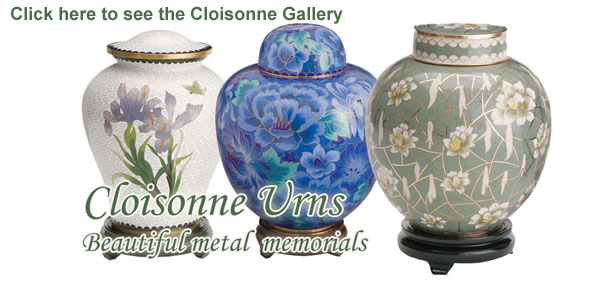

Creation Process of the Cloisonne Urn

Families are drawn to the beauty of Cloisonné urns and often are under the impression that they are made from glass or ceramic. The truth is that this style of cremation urn is made from metal. Cloisonne is a multi-stage process where colorful layers of enamel are applied to the surface of a metal object, which is then fired to become a beautiful work of art. This technique reached its perfection as a result of the efforts of Chinese artisans. Chinese cloisonné is now the standard by which the quality and beauty of cloisonné is measured worldwide and ranks as one of China's major contributions to the world's fine arts.

How A Cloisonné Urn is Made:

|

STEP 1: The meticulous process begins with gentle hammering to shape an unbreakable sheet brass core. |

|

|

STEP 2: Then an intricate design is formed using a flattened copper wire netting. |

|

|

STEP 3: Next, chosen colors of enamel are bonded to the core and fired in the kiln. |

|

|

STEP 4: This step is repeated several times to enhance the beauty and durability of the design. |

|

|

STEP 5: The urn is then gently hand-scored and polished for a smooth surface. |

|

|

STEP 6: Last, the urn is gilded to protect the brass from rust, as well as to create a lasting and bright shining finish. |

|